June 12th, 2015

Last week Principal, Theresa Casey and I attended the exciting new show by the Design Exchange highlighting the advances in 3D printing. We were very excited to see the sculptures and objects created from 3D printing technology.

Above are some of the sculptures created from 3D printers on display at the 3D-XL Printing Exhibition.

The 3DXL – (3D Printing Exhibition) is a testament to what is trending not only in design schools but the architecture industry at large. From small scale 3D printed figurines to larger-than-life detailed sculptures, the exhibition opens your eyes to what technology can achieve today. Congratulations to curator Sara Nickelson for bringing this inspired show to life.

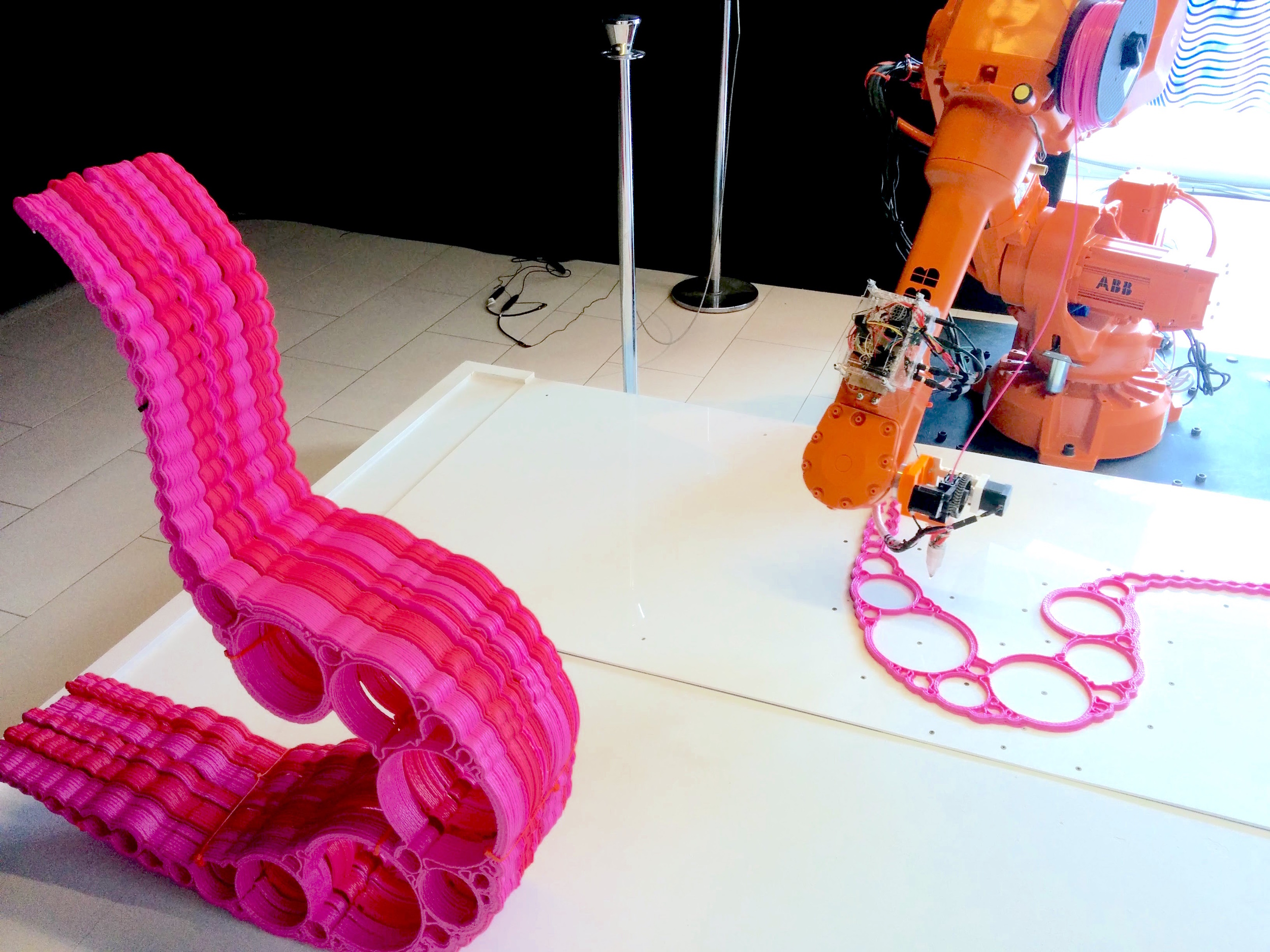

The first display features a robot-like 3D printing machine by Gilles Retsin, Manuel Jimenez-Garcia, Vicente Soler and their students from the Bartlett school of architecture. The machine simulates how each layer is printed. With the many circular shapes of this design, you can see the high accuracy printed by the robot. For many artists, it is easy to be left wandering if this 3D technology will lose the touch of the hand that good design requires.

The display of the maker-bot printers was next on display. It showcases 3D printed objects but at a smaller scale. Check out this quick video of the maker-bot printing a small-scale skull object.

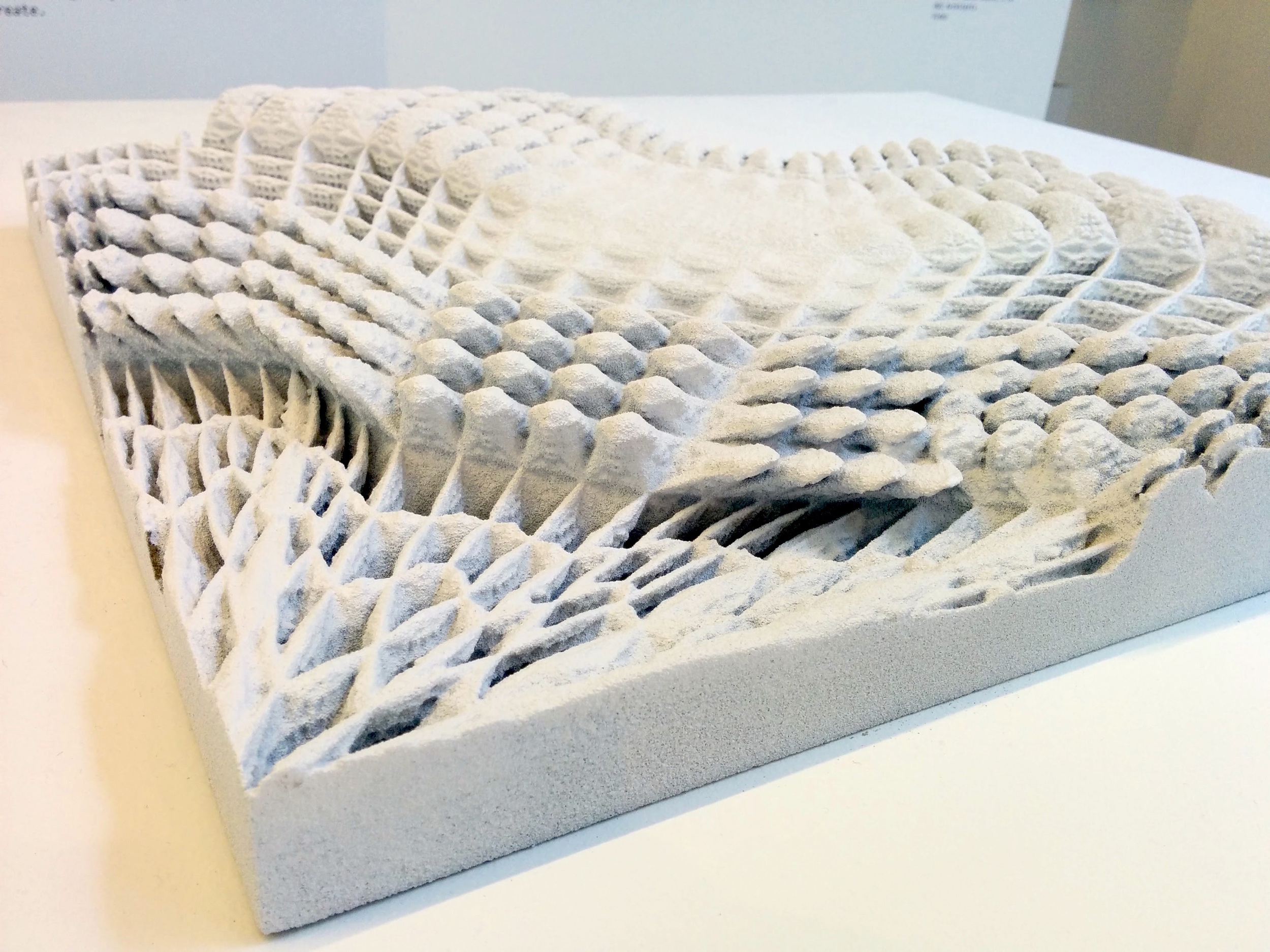

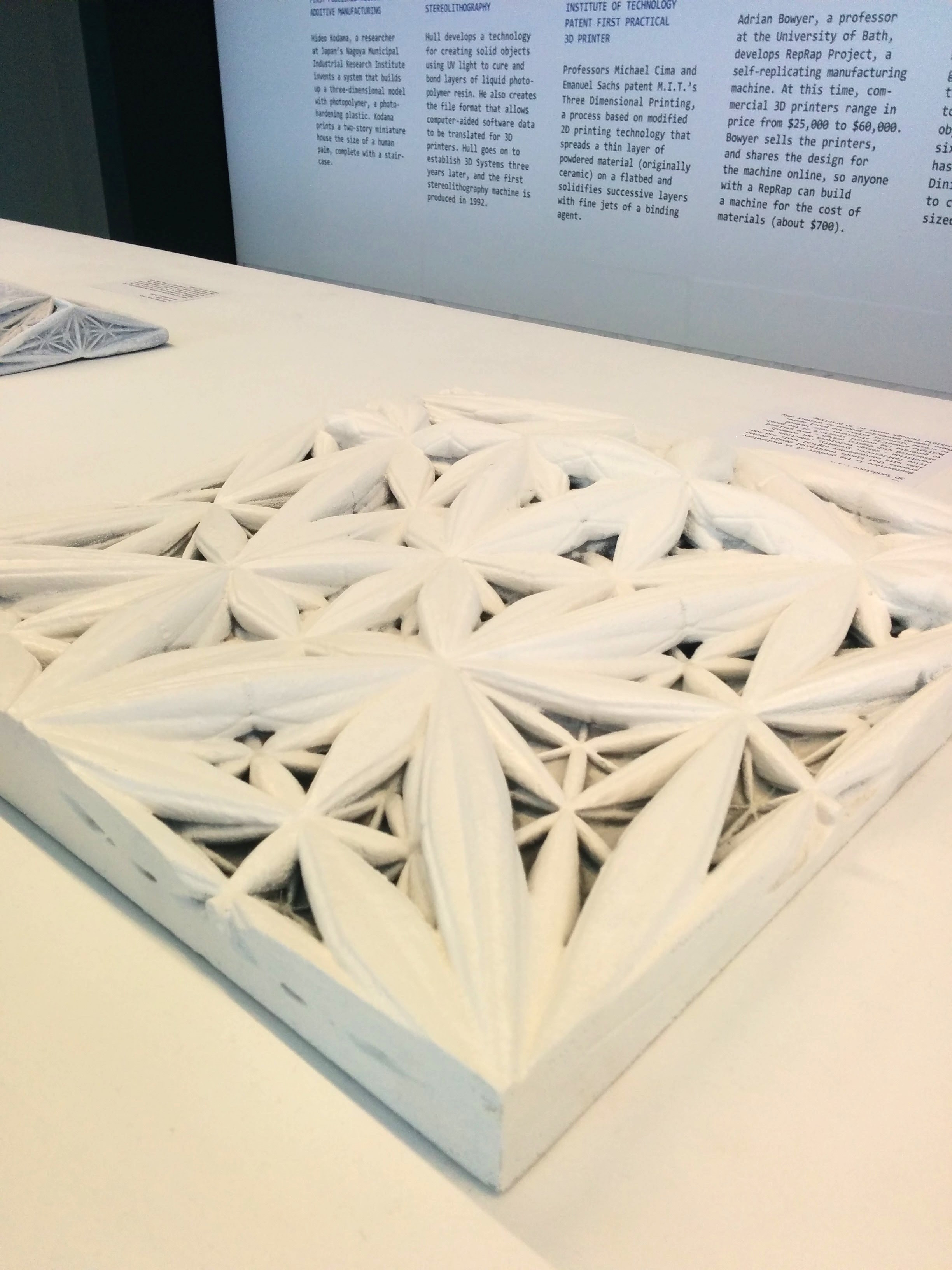

Unlike the objects from the maker-bots and the large robot printer, these 3D sandstone panels by the students at University of Toronto appear to have more of a hand-made touch. Under the guidance of Benjamin Dillenburger, professor at the John H. Daniels Faculty of Architecture, the students create panels inspired by Frank Loyd Wright’s textile blocks. These panels are made to appear and feel like sandstone, unlike the printing produced by the robot above. The organic shapes and soft edges, is for us, reminiscent of Antoni Gaudi's Sagrada Familia.

Sagrada Familia Walls, by Antoni Gaudi 3D Sandstone Print

3D Sandstone Print Sagrada Familia central apse

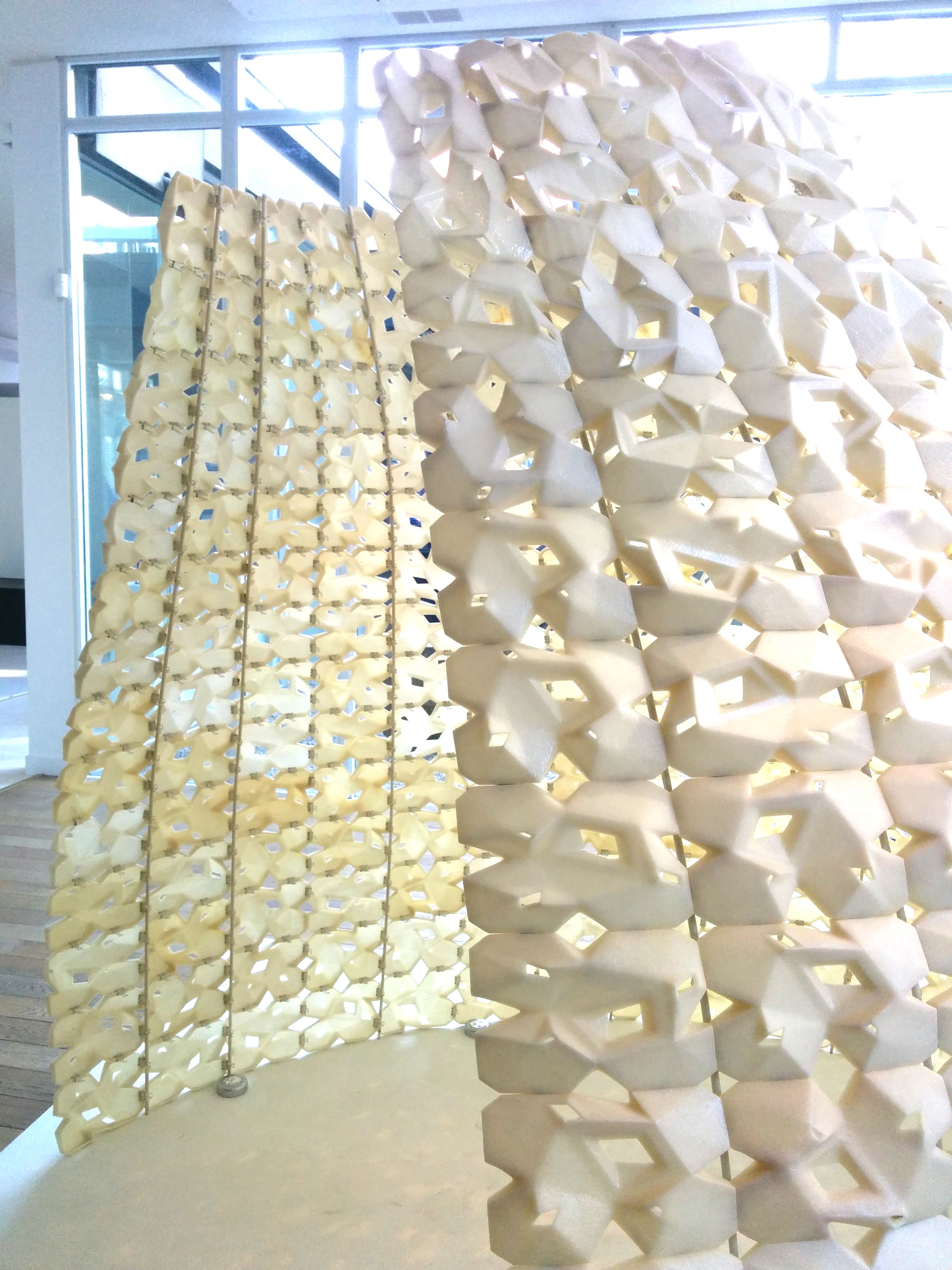

Among the most impressive 3D printed sculptures of the exhibition was the “Salty Gloo,” by Emerging Objects. An igloo-like structure made from 3D-printed salt tiles. The tiles are lightweight and translucent and against the natural sunlight from the window creates beautiful dapple shade on the exhibition ground. The colour of the natural mineral; salt and the unique shape of the tiles is the perfect combination to emit light and shade that feels organic and natural, as if sitting under a tree. This could perhaps not be achieved with conventional building materials. Have a look at the video of the Salty Gloo from the blog of the creators, “Emerging Object.” http://www.emergingobjects.com/projects/saltygloo/

Salty Gloo - Internal View Salty Gloo - Detail of an individual panel

Stepping around the corner of the last room in the exhibition, we were greeted by a larger sculpture, the “Arbesque wall,” by Benjamin Killenburger and Michaels Hansmeyer. When we saw the Arbesque wall, we decided that the technology today CAN still retain the feel of the hand-made touch needed in good design. In contrast to the smaller 3D printed objects and the designs produced by the robot printer, this sculpture is organic with undulating forms and details that are soft. The Arbesque wall is printed with the same sandstone feel and texture as the detail panels inspired by the Frank Loyd Wright textile blocks. The sandstone effect with the organic shapes of the sculpture is what sets it apart from the static 3D-printed plastic objects of the maker-bots and it also gives it the organic appearance. We were truly taken a back by its Gaudi-esk features .

An article in www.designboom.com describes the arabesque wall as, “a highly differentiated and spatially complex piece of architecture, whereby ornament and formal expression cease to be a luxury, focusing on a more unique, one-of-a-kind architecture. Pushing the boundaries of human perception, ‘arabesque wall’ offers up the tallest, entirely 3D-printed building component in stone realized to date.” The opportunities to mass produce cost effectively and quickly will soon allow 3D printing not to be the trend, but the norm. Imagine a time when both housing and monuments alike can articulate Gaudi-esk features. Perhaps this is an idea whose time has come and it won't be too far into the future before the everyday home can have the luxury of sandstone detailed walls. We cannot wait to see where this leads to and are eager to bring it into our design practice.